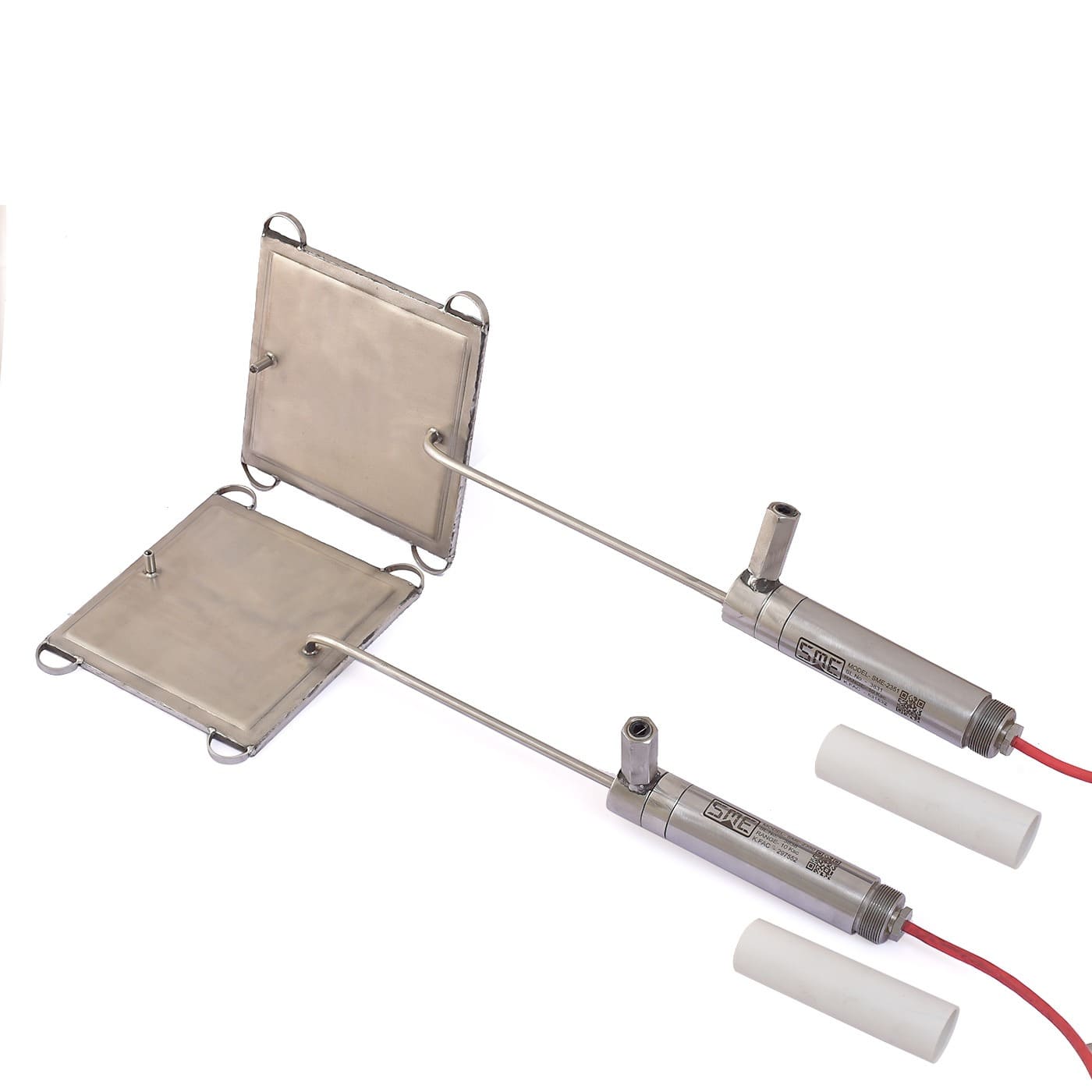

Model SME 2350 shotcrete stress cell is comprises of two rectangular steel plates welded together around the periphery & connected to a vibrating wire pressure sensor through a thin steel tubing. When stress increases in shotcrete the gape between two welded plates will change and the pressure of oil filled in between will transfer the pressure to pressure sensor. Sometimes a thermistor is also provide in sensor for temperature measurement. Due to temperature variation during shotcrete the reading of stress meter will increased and this reading will be compensated due to temp. variation.

A post stressing tube is provided in pressure sensor to overcome the gap between stress meter & shotcrete. The pressure on steel plates increases, it cause a rise in pressure in filled oil.

This pressure through thin jointing tube is transferred to vibrating wire pressure sensor. Stress meters are generally used in pair for radial stresses and for tangential stresses.